Quality

Quality is Warom’s lifeblood. The company strictly follows the requirements of lSO9001:2008 and the ISO/IEC 80079-34:2011 Quality Management System requirements for manufacturing, inspection, records processing, traceability, rectification, fault prevention and continuous improvement. Quality management is a direct responsibility of Warom’s General Manager

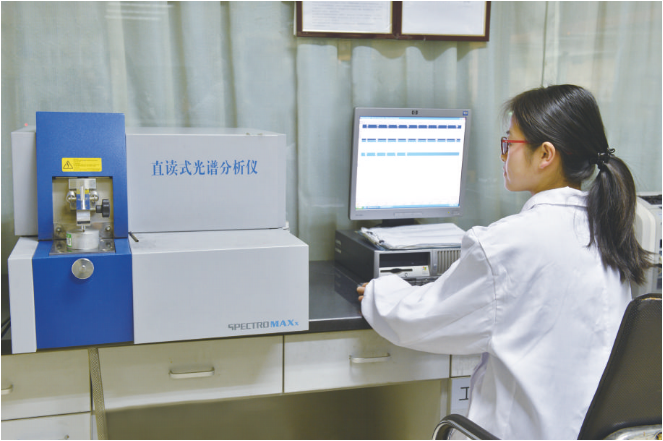

Warom has set up a quality inspection department fully equipped with a comprehensive inspection and testing center and a high-tech measurement center. Warom is an organisational member of the “China Product Quality Association” and its products and quality management organisation have been the recipient of multiple awards. Warom’s Inspection and Testing Laboratory has been the first in the industry evaluated by the China Petroleum and Chemical Industry Association as an A Grade Quality Inspection Organisation of Petroleum and Chemical Enterprise.

Attention to quality control occurs not only during the manufacturing process; additional inspection occurs before the products leave the factory. Warom makes sure that each product goes through several inspection and testing processes before it leaves the factory, and only those qualified after inspection and test are released to its customers.

The electrical laboratory can perform tests including; Glow-Wire , Tracking, Needle Flame, Insulation Resistance Measurement, Voltage Withstand testing, Low Resistance measurement, Contact Resistance measurement, Earth Resistance measurement, Lithium Battery Inner Resistance measurement and LED Luminous Flux Test and measurement.

The mechanical testing center is equipped with a Computerised Universal Hydraulic Testing Machine, a Micro-processed Spring Dynamo-meter and Impact Testing Equipment. Various tests and measurements can be performed in the center, such as Material Strength Measurement (yield strength, and tensile strength etc.), Pulling Force, Tempered Glass Impact Testing, Spring Force Measurement, Rubber Hardness Measurement and Material Hardness Measurement.

Inspections and tests that can be performed in the Environmental Testing Center include Rubber Ageing, Dust Protection testing, High & Low Temperature testing, Damp Heat test, Low Temperature Environmental Simulation testing, High Temperature Environment Simulation testing, Anti-Corrosion testing and Adhesive Force testing of Plastic Coating etc